Independent evaluations & analysis

Top line returns

🟢 Saving: √ Transportation costs. √ Storage costs. √ Fertilizer costs. √ Water costs. √ Land need / spreading. √ Discharge/gate fees. √ ++

🟢 Opportunities: √ New revenue streams. √ Nutrient Value. √ Manure Value. √ Bio-fertilizer products. √ AD feedstock/energy √ Carbon offset. √ ++

🟢 Environmental: √ GHG Emissions. √ Air Quality. √ Nutrient leaching. √ Eutrophication risk. √ Runoff risk. √ Soil Health. √ ++

🟢 Regulation: √ Regulation compliance. √ Environmental compliance. √ Improved local environment. √ Circular Agriculture. √ Scope 1 / 2 / 3 demands. √ Best Available Techniques’ √ ++

🟢 Operational: √ Efficient manure management. √ Water security. √ Targeted nutrient application. √ Animal welfare / pathogen spread. √ Highly automated / 365 monitoring. √ ++

How do we know?

To ensure our technology, systems and data are current:

► Run frequent independent analysis of our client’s input/output parameters.

► Submit output samples for EU bio-fertiliser PFC classification.

► Monitor EU Directive, Regulation, Pathways, Best Practice etc.

► Ongoing veterinary pathogen risk analysis updates.

► Access independently commissioned system evaluations and cost analysis.

► Co-ordinate with specialist engineering suppliers e.g. AD plants, separators…

3rd-party sources include: Eurecat, Aigües Manresa, Fitchner, Labin, among others.

{remove} {recover}

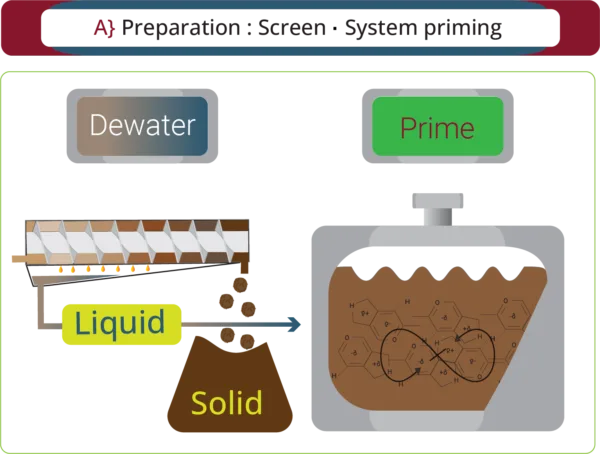

De-watering / Screening

Pig Slurry – due to the high water content, a combined ramp/screw-press system is an energy efficient method e.g. Segalés Kompack range (pictured) or ramp/vibration system.

Cow Slurry – with higher DM content, screw separators are effective for use with green bedding systems or composting.

Digestates – given their honey/treacle consistency, a prior screening is recommended to improve reactor efficiency.

Physical / Chemical Reactor

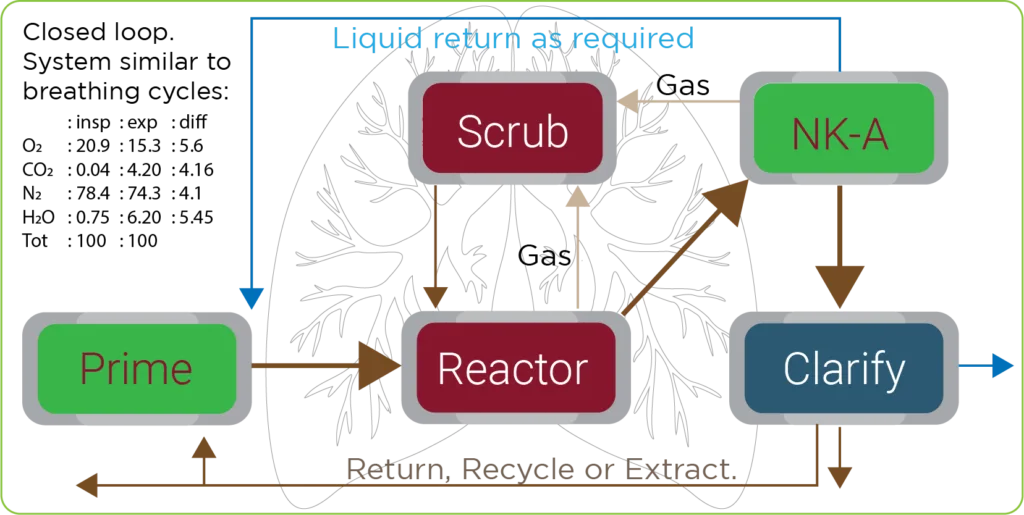

The easiest way to imagine our system is similar to breathing in and out: the intake of new, while the prior are processing, and then expelled.

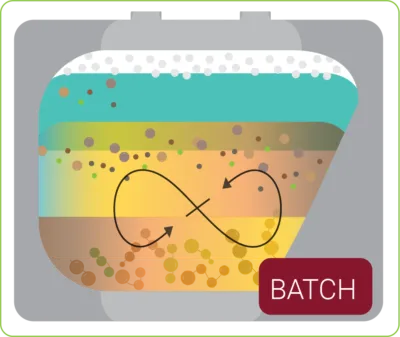

Batch reactor

Suited for producers with low volume variations or ‘cluster’ sites for multiple farms using scheduled tanker deliveries.

► System processes a fixed volume per session.

► Single bay with timed compound addition.

► Solid extracted from reactor.

► Buffer tanks regulate processing.

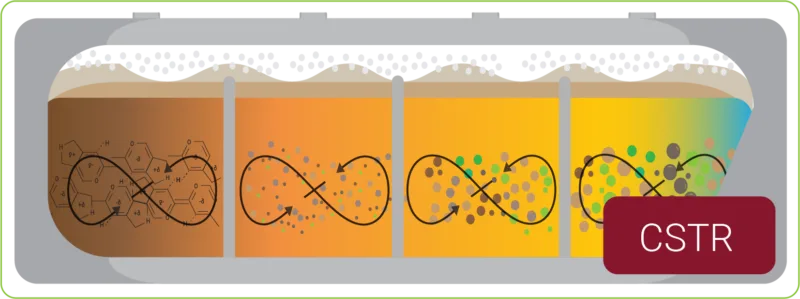

Continuous Cascade Reactor – New for 2025

The CST Reactor is our newest system innovation, developed to allow automated ‘pit to processed’ with low power requirements, efficient compound addition, reduced human intervention and volume variation through the year.

► System runs as a variable continuous flow.

► Improved coagulant performance in reactor.

► Solid removal after flocculation in clarifier.

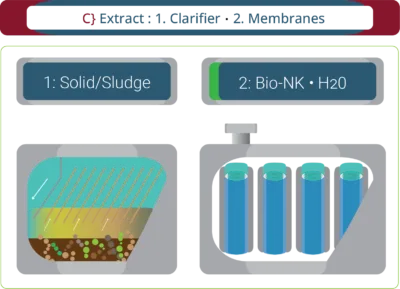

Membrane Technologies

Variable: dependent on client need / goals.

While some clients may wish to retain the untreated liquid for direct application, the final process is tailored to client’s needs.

► Water volume, reuse and purity requirements.

► Bio-NK for application needs or conversion into PFC classified bio-fertilizer.

{reuse} {refine}

Solid Fraction (DM↓N) + Liquid Fraction ‘A’ (LF-A) via Mechanical Screening

LF-A (±80%)

Suspended fine solids, ammonium nitrogen, potassium, some dissolved phosphorus. Original water content of ±87%.

=> Physical/Chemical stage.

DM↓N (±20%)

Phosphorus (bound to organic matter), organic nitrogen, fibrous solids, trace minerals.

At this point, with dry matter ±40%, the material is beyond standard classifications for ‘solid manure’ of 15-25% DM):

{reuse}

► Green bedding systems

► Anaerobic digester feedstock (reduced ammonium nitrogen content).

► Direct application for soil enrichment.

{refine}

► Composting

DM↑P + Liquid Fraction ‘B’ (LF-B) via Physical / Chemical / Clarifying.

LF-B

Predominately H20, rich in dissolved N (ammonium) & K.

=> Membrane stage.

Solid (Sludge) DM↑P

Remaining phosphorus, residual solids and organic N, trace minerals

{reuse}

► Combine and use with DM↓N.

► Combine with permeate / Bio-NK for summer application, where P required.

{refine}

►Composting.

►Commercial bio-fertilizer ingredient.

Bio-NK & Permeate H2O via Membrane technologies

Bio-NK

New 2025: A PFC organic fertilizer base source.

Concentrate

► High-N,

► High-K

► pH 6-7

{reuse}

► Fertigation,

► Direct application; growing season.

► Sale.

{refine} NEW 2025

►Concentrate for commercial PFC bio-fertiliser ingredient.

Permeate H20

ZERO DM, ZERO P, ZERO K,

► Conductivity @<0.5µS/cm,

► pH 6-7.

{reuse}

► Compliant discharge including recharging wells / watercourses.

►Farm use including washing, flushing, cooling, irrigation…

{refine}

► Connect to ‘clean water’ systems for livestock.

► Additional purification for consumption, polish….

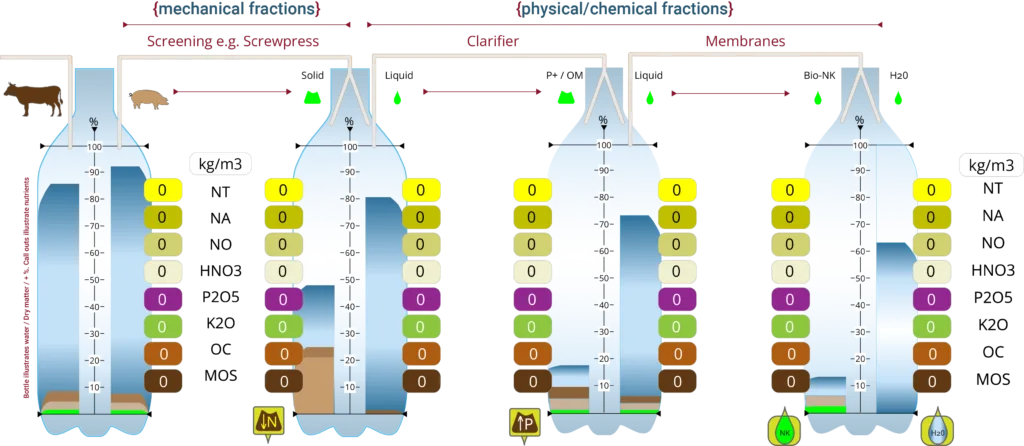

Independent analysis – pig slurry – Feb 2025

Raw

Kg/m3

| N (Kjeldhal) | 6.25 |

| N (amoniacal) | 3.54 |

| N (orgànic) | 2.71 |

| N (nitric) | 2 |

| P2O5 | 1.68 |

| K2O | 3.67 |

Combined solids

Kg/m3

| N (Kjeldhal) | 5.25 |

| N (amoniacal) | 3.22 |

| N (orgànic) | 2.03 |

| N (nitric) | 1.20 |

| P2O5 | 1.68 |

| K2O | 3.08 |

Bio-NK Liquid

Kg/m3

| N (Kjeldhal) | 3.98 |

| N (amoniacal) | 1.27 |

| N (orgànic) | 2.71 |

| N (nitric) | 3.20 |

| P2O5 | 0.00 |

| K2O | 2.35 |

Concentrate-nk @80%

Kg/m3

| N (Kjeldhal) | 19.92 |

| N (amoniacal) | 6.37 |

| N (orgànic) | 13.55 |

| N (nitric) | 16.00 |

| P2O5 | 0.00 |

| K2O | 11.74 |

Regulations

EU Directives Affecting Agriculture • European Green Deal (climate-neutral by 2050)

{nkaptur} was developed to comply with the demands of EU Directives and as much of the forward guidance given in the Green Deal as practically possible. Across Europe, governments have their own rules and regulations, then regions within each country their local by-laws and practices.

In Spain, we’ve 17 autonomous regions and fifty provinces. Even neighbours in the same water table can have very different rules regarding slurry application. Brexit just added another level of complexity.

Even so, we’re confident our technologies fulfil legal requirements across Europe; as even though we are ‘Different Countries’, we face ‘Common Challenges’ and have ‘Shared Goals’.

Rock / Hard place.

Quality sustainable and affordable food + increased legislation + instability + rising costs…. but briefly:

Current regulations + Future goals = Complexity.

We can’t follow every local bylaw change but we aim to be as up-to-date as possible across regulation amendments.

On your farm today.

✅ Cleaner water

✅ Biodiversity protection

✅ Reduced pollution

✅ Sustainable soil and land use

✅ Climate-smart agriculture

Coming soon to a farm near you.

✅ Achieve climate neutrality by 2050 (zero net emissions).

✅ Reduce pollution, water use, and biodiversity loss.

✅ Transition to a circular economy (reduce waste, reuse resources).

✅ Promote sustainable food systems under the Farm to Fork Strategy.

✅ Improve rural development and resilience to climate change.

Ongoing R&D

Pathogen reduction.

After a recent veterinary process review and discussions on viral contagion e.g. PRRS onto different sites, especially after direct slurry application though airborne dispersal, we are looking at how to expand our testing parameters to include livestock virus reductions.

Current testing: Salmonella and E-coli for EU Reuse of Water in Agriculture (2020/741), Drinking Water Directive 2020/2184…

Results for Salmonella and E-coli

► Raw: Salmonella – Detected / E-coli: 9,00E+03 NMP/g

► De-watered solids*: Salmonella – detected / E-coli: 1,50E+04 NMP/g

► Post Reactor Bio-NK & H2O: Salmonella – not detected / E-coli – 3,00E+02 NMP/g

*Pathogens can be removed through correct composting procedure, especially using reactors, where temperature control is vital.

‘Zero’ {on-site slurry}?

‘zero’-slurry may not be possible (biologically) with live animals on site, but as ‘near-zero’ as possible: solids used for AD or composting reactors, Bio-NK liquid sent for bio-fertilser production and water discharged or reused, could it be possible to have ‘near-zero’ on-site slurry?

‘Zero’ {land/disposal requirements}?

For farms where land disposal is a problem, with >60% of the original content permeate water, the opportunity to repurpose solids and Bio-NK storage a fraction of the original volume and suitable for PFCs – what turns slurry from a liability to an opportunity?

This is not intended to be a full list of EU/UK…. legislation but some of the main criteria relating to our farming communities. If there are regulations related to your specific region or circumstances that we should know about, please get in touch via our contact form or email us: projects@nkaptur.com

You can find out more regarding pan-EU regs at EUR-Lex, e.g. Nitrates EUR-Lex Link Water EUR-Lex Link Habitats EUR-Lex Link Birds EUR-Lex Link Pesticides EUR-Lex Link (CAP) Link / Link / Link Emissions EUR-Lex Link Renewable EUR-Lex Link Landfill EUR-Lex Link Climate EUR-Lex Link.